A high-quality milk powder can only be achieved by carefully handling the milk throughout its whole lifecycle, from receipt to powder. No matter what kind of milk you're making—skim, whole, instant whole, fat-filled, or any other variation—SM Engineering has the solution for you.

SM Engineering provides dairy-based milk powder products and is a leading global supplier of integrated processing units. As an internationally renowned technological partner to industry, we bring decades of expertise to the table. Plants developed, configured, and equipped by SM Engineering convert millions of liters of milk per day into dry milk products all over the globe. Milk powder plants are SM Engineering's forte; we create, fabricate, and set them up. We have become a household brand in the dairy processing sector thanks to our dedication to innovation, quality, and customer happiness. Whether you are a big-scale industrial producer or a small-scale dairy farmer, we have solutions that are tailored to your needs.

Milk powder is an adaptable and practical form that may be further processed into many other goods. When local milk is either too expensive or too scarce, powder is usually mixed on the spot and used in place of liquid milk. Powdering milk is an efficient method of transporting milk over long distances since it increases its shelf life and decreases transportation expenses. Producing milk powder, together with the relatively inexpensive packaging and storage options, allows farmers to manage supply and demand better.

The expanding milk powder market is a good fit for SM Engineering's energy-efficient evaporators and dryers. In order to help companies achieve their goals of cost-effective and efficient manufacturing, we have developed solutions that take advantage of economies of scale. We have spray dryers for dairy products and evaporators that reach heights of up to 20 meters with fans powered by motors ranging from 600 to 700 kW.

1. State-of-the-Art Technology:Our milk powder plants are equipped with the most recent innovations in dairy processing technology, guaranteeing that they are efficient, dependable, and capable of generating top-notch goods.

2. Better Solutions:We know that every dairy operation is different, which is why we provide customized solutions. Together, you and our team will determine your unique needs and goals for the milk powder factory, and then we will design and build it to your exact specifications.

3. Unparalleled Quality:Our commitment to excellence is fundamental to everything we do. The use of premium materials and components in the construction of our milk powder plants guarantees their longevity and optimal performance.

4. Assistance Services:We provide extensive assistance to make sure your milk powder production runs well. Our skilled staff is there for you from the very beginning, from the consulting and design phase all the way through installation, training, and continuing maintenance.

5. Affordable Solutions:In today's cutthroat industry, we know how important it is to have solutions that won't break the bank. When you engage with us, we'll identify the most cost-effective ways to accomplish your production objectives while staying within your budget.

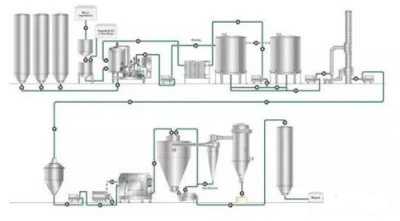

Making high-quality milk powder relies on efficiently collecting and storing raw milk. Our storage tanks and sanitary collecting systems maintain optimal conditions for raw milk.

Pasteurizers, separators, and homogenizers are all part of our top-of-the-line milk processing equipment. These technologies preserve the nutritional value and purity of the milk during the processing of milk into powder.

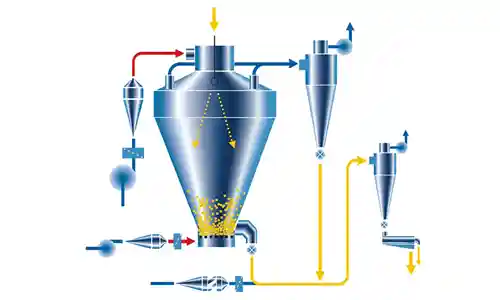

One of the most critical steps in making milk powder is spray drying. Our spray drying technology guarantees the effective transformation of liquid milk into powder. In order to keep the milk powder's quality and consistency intact, we offer accurate temperature control and consistent drying.

Our range of solutions covers all aspects of powder handling and packaging, from conveying to filling, sealing, and labeling systems. The milk powder will stay fresh and in good condition with the help of our packaging equipment, which also provides appealing and functional solutions for storage.

Creativity: Adapting technological solutions to the ever-changing demands of the dairy sector.

Quality:Making sure that all of our activities are at the highest possible level.

Goal-Oriented:Ensuring Customer Satisfaction via the Provision of Tailored Solutions and Support.

Sustainability:Supporting eco-friendly methods in the production of dairy products.

Milk collection center equipment manufacturer, SM Engineering, provides unwavering assistance to milk-collecting centers worldwide. Our equipment guarantees high levels of quality, efficiency, and dependability, and it is tailored to satisfy the varied demands of dairy farmers in various locations.

If you're looking for a partner in the manufacturing of a Whey Processing Plant, go no further than SM Engineering. When you combine our dedication to quality and customer service with our creative ideas, we become the perfect partner for all of your dairy processing needs.